Meriden, Conn. – When a major crime is committed in the State of Connecticut, investigators turn to the professionals at the state’s Forensic Science Laboratory in Meriden for help. When the professionals at the Forensic Science Laboratory needed help, they turned to The Nutmeg Companies and ETTER Engineering.

The Nutmeg Companies, a local General Contracting firm whose main focus is on public work (specifically, federal government renovation, repair, remodeling and new construction) throughout New England, New York, New Jersey, Maryland, Virginia, and Georgia, was hired to complete a two-story, 22,000 square foot addition to the facility. The new space includes additional offices, mechanical and electrical rooms, as well as laboratory space. When it was determined the available street pressure of 5” WC was insufficient to supply the two hot water boilers, one hot water heater and two roof top units, the contractors called ETTER Engineering for help.

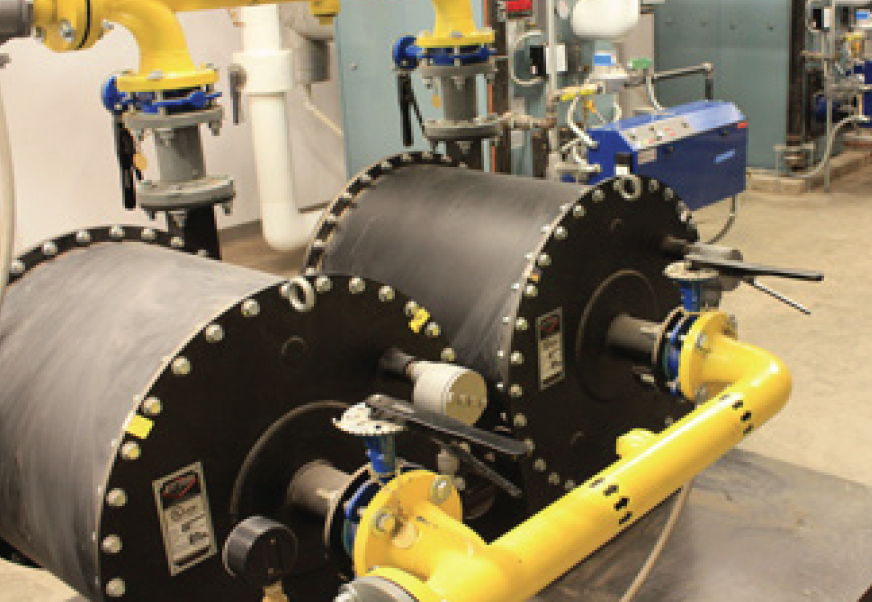

The application called for a 9” WC boost to be provided, for which ETTER specified a pair of ENGB3 (ETTER Next Generation Gas Booster) units designed to run in a lead-lag setup to balance run-time on each booster; the lead-lag setup also provides backup in the unlikely case of an emergency. Whereas other manufacturers were only willing to provide loose components, ETTER immediately understood the importance, from an ease of install and cost standpoint, of providing a complete system to Nutmeg. According to Project Manager Andy Beatty, ETTER’s willingness to “[take] the initiative to look over the plans and specs and provide a complete skid-mounted, fully piped and wired package that our crews would only need to connect to” was a key factor in his decision to go with an ENGB gasPODTM packaged booster system.

When asked what he thought about working with ETTER on the project, Beatty replied, “ETTER was good to work with. Their submittals were timely and complete, wthe unit arrived when they said it would; we had several questions during construction that they answered, and [they] actually came out to the job to speak with our foreman. They started the unit within the time frame we asked for and provided the reports we needed when we needed them.”

A third-generation family owned company, ETTER Engineering has been building packaged gas booster systems longer than anyone in the business. As Vice President of Engineering Sales, Jon Moore, says, “the ability to deliver a packaged system with no technical risk is very attractive to our customers. They simply need to place the order, and ETTER handles the rest!”